MICROWAVE CABLE ASSEMBLIES

We offer fit for purpose solutions, microwave cable assemblies designed to meet your technical requirements, both electrical and mechanical for any demanding application. We do so within your budget or succeed in decreasing the cost levels with your current suppliers. Our microwave coaxial cables are designed to perform with the lowest possible losses, due to an optimized construction and use of the best materials available.

ULTRA LOW LOSS MICROWAVE CABLE ASSEMBLIES

Gigalink MCE delivers to the most demanding markets: aerospace and defense as well as to telecommunication and test and measurement applications. Our range of ultra low loss microwave cables have been designed to perform with the lowest loss possible. Consequently, these cables have a solid inner conductor and are therefore not recommended for use where multiple flexes under low radii are requested.

DC - 50 GHz

Ø 3,3 mm

3,4 dB/m at 50 GHz

Available Connectors

SMA - 2,4

DC - 40 GHz.

Ø 4,0 mm

2,1 dB/m at 40 GHz.

Available Connectors

NP - TNCP - SMA - 3,5 - 2,9

DC - 26,5 GHz

Ø 5,2 mm

1,3 dB/m at 26,5 GHz

Available Connectors

NP - TNCP - SMA - 3,5 - 2,9

DC - 18 GHz

Ø 7,9 mm

0,65 dB/m at 18 GHz

Available Connectors

SMA - TNCP - NP - 7/16

12 GHz. microwave coaxial cable close to a combustion engine being exposed to 600 degree for 2 minutes, resisting high vibrations, G-forces and also stringent salt fog requirements.

This cable needed special mechanical protections as well as thermo-conductive layers to cope with the high temperature. The connectors have been designed specially to withstand the heat but also the salt-fog requirements.

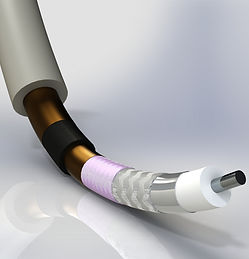

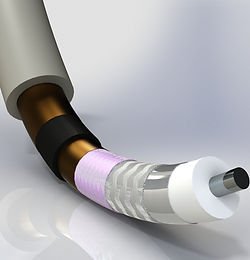

FLEXIBLE ULTRA LOW LOSS

MICROWAVE CABLES

This range has of coaxial cables have an inner conductor made out of multiple strands making them suitable for any flexible application, average to 25.000 bends. Our microwave cable assemblies ensure optimum stability in phase and attenuation amplitude. The construction of this range of cables is such that we have the lowest attenuation available for cables with a flexible inner conductor.

65 Ghz.

DC - 50 GHz

Ø 3,3 mm

3,8 dB/m at 50 GHz

Available Connectors

DC - 40 GHz

Ø 4,0 mm

2.9 dB/m at 40 GHz

Available Connectors

DC - 26,5 GHz

Ø 5,1 mm

1,8 dB/m at 26,5 GHz

DC 18 GHz

Ø 8 mm

1,07 dB/m at 18 GHz

SMA - 2,4

NP - TNCP - SMA - 3,5 - 2,9

NP - TNCP - SMA - 3,5 - 2,9

SMA - TNCP - NP - 7/16

DC - 12GHz

Ø 10,3 mm

0,5 dB/m at 12 GHz

Available Connectors

SMA - NP

Microwave coaxial cable assemblies being able to flex at -55 degree C.

A special 34 GHz. application where the cable needed to be flexed at -55 degree C. In this case we have replaced the jacket with a 100% pure silicone, able to easily perform these flexes and handling the low temperature without any problem.

Available Connectors

Available Connectors

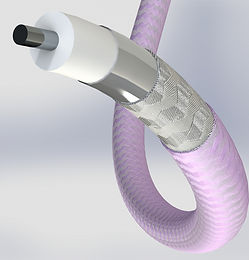

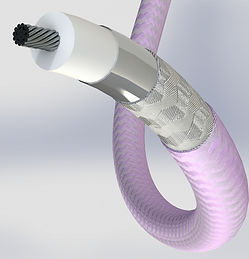

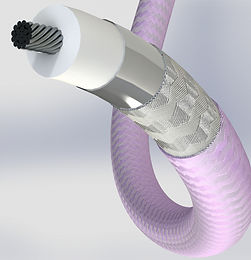

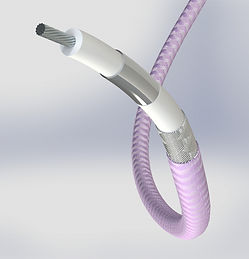

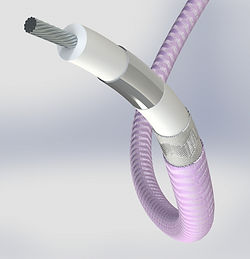

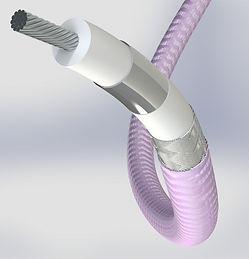

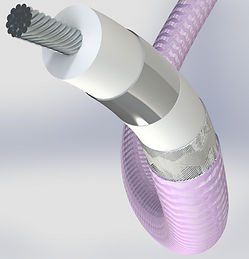

ULTRA FLEXIBLE ULTRA LOW LOSS

MICROWAVE CABLES

When it comes to real stability under a high number of flexes, this is the range of cables you are looking for. Proven track record in applications where up to a million flexes are made, the stability and long flex life of these microwave cables are outstanding.

These cables are designed to flex!

As one of our customers stated: “After testing many different cables we came to the conclusion that this is really the best cable on the planet for dynamic applications.”

65 Ghz.

DC - 50 GHz

Ø 3,5 mm

3,8 dB/m at 50 GHz

Available Connectors

DC - 40 GHz

Ø 4,1 mm

2,9 dB/m at 40 GHz

Available Connectors

DC - 26,5 GHz

Ø 5,3 mm

1,8 dB/m at 26,5 GHz

Available Connectors

DC - 18 GHz

Ø 8,0 mm

1,07 dB/m at 18 GHz

Available Connectors

SMA - 2,4

NP - TNCP - SMA - 3,5 - 2,9

NP - TNCP - SMA - 3,5 - 2,9

SMA - TNCP - NP - 7/16

16 phase-matched assemblies ... GHz. in a continuous flexing application, humid environment.

This set of microwave able to keep the same phase match variations after hundreds and thousands of bends, in a moisture environment. The cable used is for us relatively standard, the design of the moisture blocked connectors is special, also given the fact that the cables are strongly bended right after the connectors.

SHIPBOARD ULTRA LOW LOSS

MICROWAVE CABLES

DC - 26,5 GHz

Ø 13,2 mm

1,3 dB/m at 26,5 GHz

Available Connectors

DC - 18 GHz

Ø 16,5 mm

0.65 dB/m at 18 GHz

Available Connectors

SMA - TNCP - NP - 7/16

NP - TNCP - SMA - 3,5 - 2,9

In 1994, we were asked to design a microwave cable specifically for use on naval vessels where all cables are normally installed unprotected, which is not good for microwave coaxial cables that lose their electrical performance once damaged.

Able to withstand mechanical impact from outside, easy installation by means of ty-wraps, simplified connector construction for easy repairs and outstanding performance, these microwave cables benefit from an exceptionally long flex life. Our solution proofs its reliability, after 20 years of use the degradation in insertion loss is less than 1%. Our confidence is resulting in a lifetime guarantee for these cables.

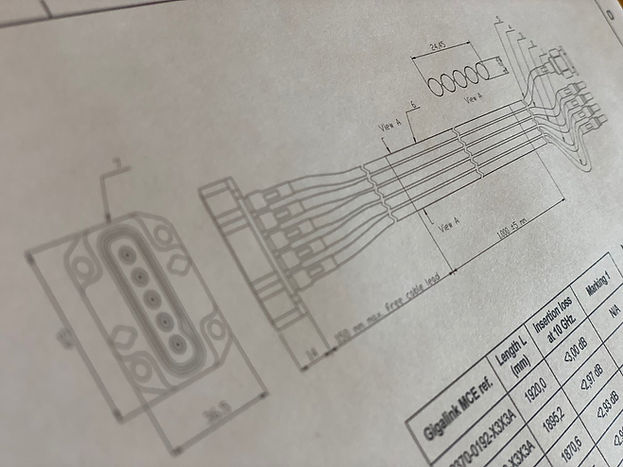

Ask for a quote

When we quote microwave cable assemblies to you for your specific flexible application, we will issue a detailed drawing with a relevant and important electrical and mechanical characteristics. Gigalink MCE will gladly help you designing your connection systems using all our experience and the knowledge of our partners. Do you want more information about the long flex life of our microwave cables or a custom solution? Please contact us for more information. You can reach us at +31 (0)10 789 1122 or via email at qstn@gigalink-mce.com.